Battery load testing represents the most reliable method for determining actual battery performance under real-world conditions. Unlike simple voltage measurements that only show electrical potential at rest, load testing evaluates how well a battery delivers power when demanded. This comprehensive testing approach reveals battery weaknesses that other methods miss, providing accurate assessments of battery health and reliability.

Understanding proper load testing procedures ensures you obtain meaningful results that guide battery management decisions. Whether testing automotive batteries, backup power systems, or portable device batteries, following established protocols delivers consistent, actionable information about battery condition and remaining service life.

Understanding Battery Load Testing Fundamentals

Battery load testing involves applying a controlled electrical load to a battery while monitoring its voltage response. The test simulates actual usage conditions by drawing current from the battery at specified rates, typically based on the battery’s capacity rating or intended application requirements.

During load testing, a healthy battery maintains stable voltage under load, while degraded batteries show significant voltage drops or an inability to sustain the required current. The magnitude and pattern of voltage changes during testing provide detailed insights into battery condition that static measurements cannot reveal.

Why Load Testing Provides Superior Assessment

Static voltage measurements only indicate the battery’s electrical potential without load, similar to measuring water pressure in a pipe without opening any faucets. A battery might show perfect voltage when not delivering current, but fail dramatically when required to power actual devices.

Load testing reveals the battery’s ability to deliver sustained power, which directly relates to real-world performance. This dynamic assessment identifies batteries with high internal resistance, reduced capacity, or other problems that prevent reliable operation under normal conditions.

Types of Battery Load Testing

Constant Current Load Testing

Constant current testing applies a steady electrical load for a specified duration while monitoring voltage stability. This method works well for batteries used in applications requiring steady power output, such as backup lighting or emergency systems.

The test typically involves applying a load equal to the battery’s rated capacity divided by a time factor, such as C/10 (capacity divided by 10 hours) or C/20 for gentler testing. Voltage measurements throughout the test period reveal how well the battery maintains performance under sustained load.

High-Rate Discharge Testing

High-rate discharge testing applies heavy loads for short periods to simulate high-demand applications like engine starting or power tool operation. This testing method uses loads several times higher than normal operating current to stress-test battery performance.

A load battery tester designed for high-rate testing can apply currents of 100 amperes or more for periods of 10-30 seconds. The battery’s ability to maintain adequate voltage during these high-demand periods indicates its suitability for high-performance applications.

Essential Equipment for Battery Load Testing

Selecting the Best Battery Load Tester

Choosing the best battery load tester depends on your specific testing requirements, including battery types, voltage ranges, and current levels you need to evaluate. Professional automotive testers handle high currents for engine starting batteries, while electronic device testers work with lower currents and voltages.

Key features to consider when selecting testing equipment include:

- Current capacity appropriate for your battery types

- Voltage range covering all batteries you test

- Timer functions for standardized test durations

- Digital displays for accurate readings

- Safety features to prevent overheating or damage

Quality load testers include thermal protection to prevent overheating during extended testing and automatic shutoff features that terminate tests when batteries reach dangerous voltage levels.

Additional Testing Equipment

Accurate battery load testing requires supporting equipment beyond the primary load tester. Digital multimeters provide precise voltage measurements before, during, and after load tests. Temperature measurement tools ensure testing occurs within specified temperature ranges for accurate results.

Battery terminal cleaners and protection equipment maintain good electrical connections during testing. Poor connections can introduce resistance that affects test results, making proper terminal preparation necessary for reliable measurements.

Step-by-Step Load Testing Procedures

Pre-Test Preparation

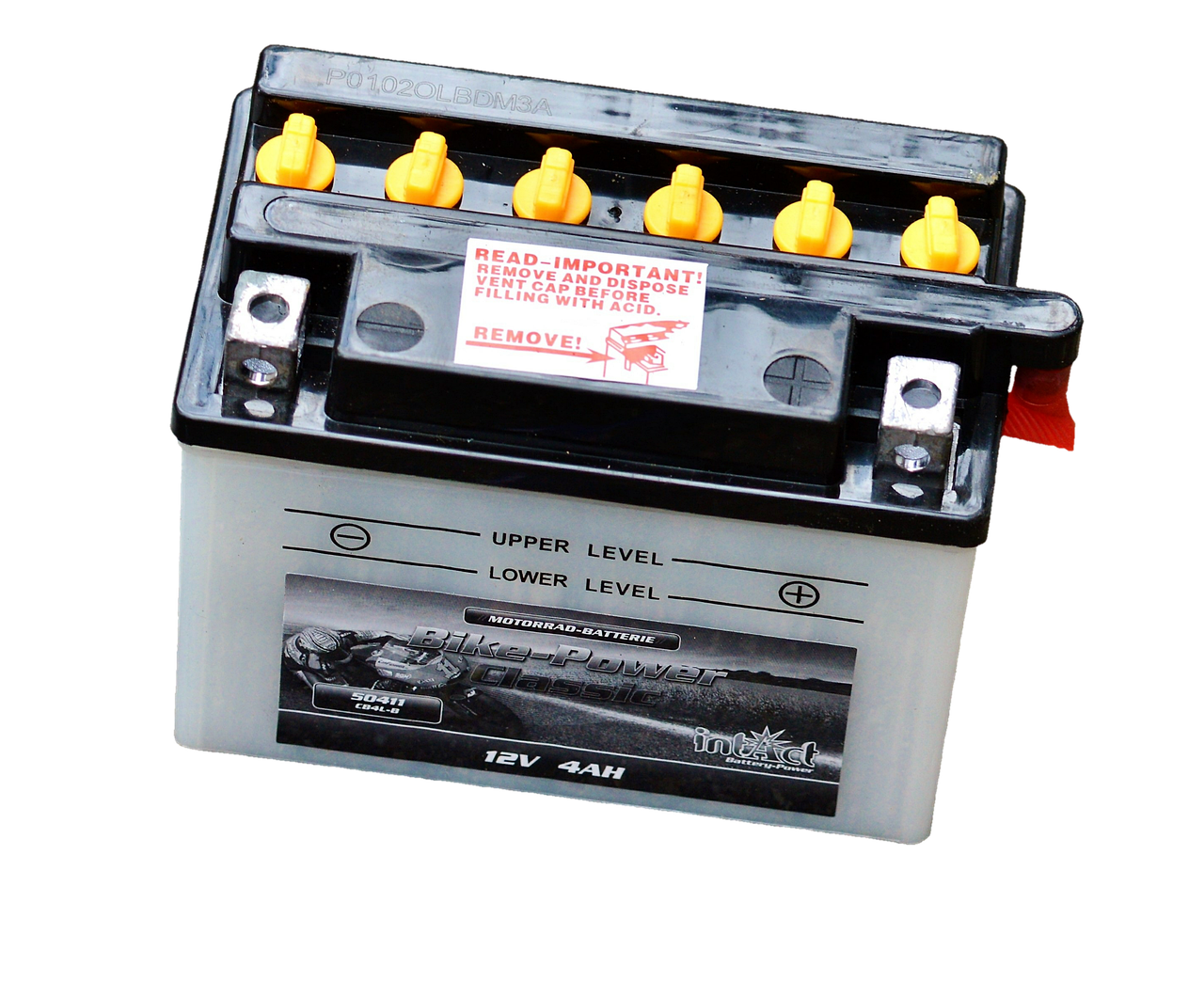

Proper preparation ensures accurate and safe battery load testing results. Begin by inspecting the battery for physical damage, leakage, or corrosion that might affect performance or create safety hazards. Clean battery terminals thoroughly to ensure good electrical connections.

Record battery specifications, including voltage, capacity, and chemistry type. Check the battery’s service history and age if available, as this information helps interpret test results. Allow batteries to reach ambient temperature if they have been stored in extreme conditions.

Verify that your load battery tester is properly calibrated and functioning correctly. Check all connections and cables for damage that could affect test accuracy or create safety risks.

Conducting the Load Test

Connect the load tester according to the manufacturer’s instructions, ensuring secure connections to both battery terminals. Select the appropriate load setting based on the battery’s capacity and intended application. Most automotive testing uses loads of half the battery’s cold cranking amp rating.

Apply the load for the specified test duration, typically 10-15 seconds for automotive batteries or longer periods for deep-cycle applications. Monitor voltage throughout the test period, noting both the initial voltage drop and the final sustained voltage under load.

Record all measurements systematically, including pre-test voltage, voltage under load, and recovery voltage after removing the load. Note the ambient temperature and any unusual observations during testing.

Interpreting Test Results

Battery load testing results indicate battery condition through voltage performance under load. Healthy batteries maintain voltage above specified minimums throughout the test period, while degraded batteries show excessive voltage drops or an inability to sustain the required current.

For 12-volt automotive batteries, voltage should remain above 9.6 volts during standard load testing at 70°F. Lower temperatures require adjustment of acceptable voltage levels, as cold conditions reduce battery performance even in healthy batteries.

Compare test results against battery specifications and industry standards for your specific battery type and application. Document results for future reference and trend analysis.

Safety Considerations for Battery Load Testing

Electrical Safety Precautions

Battery load testing involves high currents and stored electrical energy that can cause injury if handled improperly. Always wear appropriate safety equipment, including safety glasses and insulated gloves, when handling batteries and test equipment.

Ensure adequate ventilation during testing, particularly for lead-acid batteries that may release gases. Never smoke or create sparks near batteries during testing, as some battery types can produce flammable gases.

Use insulated tools and maintain good housekeeping around testing areas. Keep test areas clear of metal objects that could create accidental short circuits during testing procedures.

Equipment Safety Features

Modern load battery testers include various safety features designed to protect both equipment and users during testing. Thermal protection prevents overheating during extended tests, while automatic shutoff features terminate tests when voltages drop to dangerous levels.

Reverse polarity protection prevents damage if connections are made incorrectly, though proper connection procedures should always be followed. Some testers include spark-proof connections that minimize arcing during connection and disconnection.

Advanced Load Testing Techniques

Temperature-Compensated Testing

Battery performance varies significantly with temperature, making temperature compensation necessary for accurate load testing results. Cold temperatures reduce battery capacity and increase internal resistance, while high temperatures can mask developing problems.

Professional testing protocols specify temperature corrections for test results, allowing accurate assessment regardless of ambient conditions. Some advanced load testers include automatic temperature compensation based on built-in temperature sensors.

Trending and Data Analysis

Regular load testing creates performance histories that reveal battery degradation trends over time. Systematic data collection and analysis identify declining performance before complete failure occurs, enabling proactive replacement planning.

Graphing voltage performance over multiple test cycles shows gradual capacity loss and helps predict when replacement becomes necessary. This predictive approach prevents unexpected failures while avoiding premature replacement of functional batteries.

Common Load Testing Mistakes

Inadequate Load Application

One frequent error involves applying insufficient load during testing, which fails to stress the battery adequately to reveal developing problems. Light loads may not expose capacity loss or internal resistance increases that affect real-world performance.

Always use load levels specified for your battery type and application. Automotive batteries require high-current testing to simulate starter motor demands, while deep-cycle batteries need sustained load testing that matches their intended use patterns.

Poor Connection Quality

Corroded or loose connections during load testing introduce resistance that affects the accuracy. Clean terminals thoroughly before testing and ensure tight, secure connections throughout the testing process.

Poor connections can make good batteries appear defective or mask problems in failing batteries. Proper terminal preparation and connection procedures ensure test results reflect actual battery condition rather than connection issues.

Maximizing Load Testing Effectiveness

Regular battery load testing provides valuable insights into battery performance that guide maintenance and replacement decisions. By following proper procedures and using appropriate equipment, you can obtain accurate assessments that prevent unexpected failures and optimize battery investments.

The key to effective testing lies in using consistent procedures, proper equipment, and systematic data recording. Whether you’re maintaining a single battery or managing large battery systems, load testing provides the information needed for informed battery management decisions.