Key Highlights

- A pre-task plan (PTP) is a proactive strategy to organize daily work and identify potential hazards before they cause issues. Effective pre-task planning enhances construction safety by incorporating job hazard analysis and establishing clear control measures. However, traditional pre-task planning methods can have limitations, such as relying heavily on generic templates that may not address specific job hazard scenarios, overlooking evolving site conditions, and sometimes failing to engage all team members in the task planning process. These gaps can lead to incomplete identification of potential hazards and inadequate control measures.

- Effective pre-task planning enhances construction safety by incorporating job hazard analysis and establishing clear control measures.

- The process boosts productivity by providing clear roles and improving communication among team members on the job site. For effective pre-task planning toolbox talks, it’s best to review the job’s scope, identify potential hazards, involve all team members in discussing controls, and ensure everyone understands their individual responsibilities. Implementing a PTP helps build a strong culture of safety management and accountability within your crew.

- Implementing a PTP helps build a strong culture of safety management and accountability within your crew.

- Modern digital tools and customizable templates can simplify the PTP process, ensuring consistency and thoroughness.

Introduction

In the fast-paced construction industry, safety and efficiency are crucial. Effective task planning, such as a pre-task plan (PTP), sets teams up for success by shifting from reactive to proactive work. This simple, structured approach ensures safety and productivity are built in from the start.

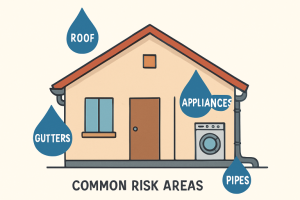

When conducting pre-task risk assessments, there are some common mistakes to avoid. These include overlooking site-specific hazards, failing to update assessments as conditions change, neglecting to involve all team members in the process, and relying on generic checklists rather than tailored analysis. By being mindful of these pitfalls, teams can further enhance their safety and efficiency.

Understanding Pre-Task Planning in Construction Projects

A pre-task plan (PTP) is a detailed outline that your team creates before starting a job. It organizes steps, identifies risks, and sets safety controls for construction projects. More than paperwork, it’s a key communication tool.

Making PTPs a daily habit ensures consistent processes across sites and helps crews start each day with a clear, safe plan. This proactive approach is essential for project success. Let’s look at what PTPs include and why they matter.

Definition and Purpose of Pre-Task Plans

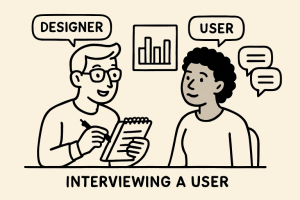

A pre-task plan (PTP) is a game plan created before work begins. The crew meets to discuss the job, outline steps, and identify challenges, turning safety rules into practical actions.

The main goal is to formalize planning, promote awareness, and encourage the team to consider hazards and safety measures before starting. This shared understanding helps keep everyone safe and organized on site.

Why Pre-Task Planning is Essential for Project Success

Pre-task planning is essential for effective safety management and project success. By identifying hazards in advance, teams can prevent incidents and move from a reactive to a proactive approach.

A solid pre-task plan fosters a safe, productive environment. Involving workers in planning boosts morale, engagement, and quality, and reduces mistakes and downtime.

This process builds trust and awareness, empowering everyone to take ownership of safety. Planning for risks actively protects your team and supports project success.

Key Benefits of Effective Pre-Task Planning

A consistent pre-task planning routine offers benefits beyond compliance. It makes hazard identification a daily habit and integrates job hazard analysis into everyday tasks. Engaging the whole crew in planning increases ownership, leading to safer, more productive workdays. The following sections explain how PTPs enhance safety and team performance.

Enhancing Workplace Safety and Health

Pre-task planning dramatically improves workplace safety and health. By analyzing tasks beforehand, teams can identify hidden risks and address them with targeted safety measures, rather than relying on generic protocols. This proactive approach leads to:

- Fewer incidents and injuries

- Better adherence to safety procedures

- A stronger culture of shared responsibility

- Reduced work stoppages due to accidents

Boosting Team Productivity and Communication

While safety is the main priority, pre-task planning also boosts productivity. Clear daily work processes allow teams to work confidently and efficiently, reducing confusion and wasted time.

Planning encourages open communication and accountability. Everyone understands their role and how it fits into the larger task, which streamlines workflows and improves morale. Better communication also helps resolve issues before they cause delays.

Productivity benefits include:

- Fewer reworks and mistakes

- Better coordination between teams

- Enhanced problem-solving

- A more organized, efficient work site

Core Steps in the Pre-Task Planning Process

A structured pre-task planning (PTP) approach ensures no critical steps are missed and maintains consistency across crews and job sites. Combining job safety analysis with practical planning makes PTP simple and repeatable. The next sections cover identifying the job scope, assessing hazards, and creating your plan.

Identifying Job Scope and Objectives

Effective task planning starts with clearly defining the work. Break down the overall goal into specific tasks and establish a workflow for the day. Involve the entire crew in discussing objectives and key steps to ensure alignment.

To define the scope, cover:

- Specific tasks to complete

- Required tools and equipment

- Personnel roles

- Expected timeline

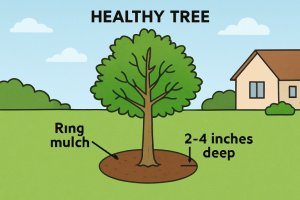

Recognizing and Assessing Task Hazards

Once the job scope is clear, conduct a risk assessment through job hazard analysis (JHA). Walk through each task step and identify potential hazards—avoid being vague or rushing. Encourage the team to consider what could go wrong.

A JHA is part of a pre-task plan (PTP), not a separate document. While JHA identifies hazards and controls, the PTP includes roles, materials, and communication strategies.

Use a simple framework: for each hazard, note the potential harm and control measure.

| Hazard Type | Potential Harm | Control Measure |

| Working at height | Falls | Use fall arrest systems, inspect equipment |

| Electrical work | Electric shock, burns | De-energize circuits, use insulated tools |

| Heavy lifting | Back strain, muscle injury | Use lifting aids, proper technique |

| Trenching | Cave-in, engulfment | Use trench boxes/shoring, keep spoil pile away |

Building a Comprehensive Pre-Task Plan

With the scope defined and hazards assessed, it’s time to formalize your task plan. A comprehensive PTP is more than a list of dangers; it’s a complete guide for the day’s work. It should include the necessary control measures for each identified risk and serve as a reference point for the crew.

This document shouldn’t be static. Encourage your team to treat it as a tool for continuous improvement, updating it if conditions change. This helps prevent costly reworks and ensures the plan remains relevant throughout the task. The next steps involve assigning roles and using the right tools to make this process seamless.

Assigning Roles and Responsibilities

A plan works only when everyone knows their role. Assign clear responsibilities based on each team member’s skills to ensure accountability and eliminate confusion. Designate leaders, safety monitors, and make sure all stakeholders, including subcontractors, are informed of their duties.

Use digital planning tools to document and share roles, keeping the team aligned and streamlining implementation.

Utilizing Checklists and Planning Templates

Using standardized tools ensures consistency and thoroughness. Pre-task planning templates and checklists give your team a clear structure, eliminating guesswork and reducing the risk of missing critical information—unlike informal paper-based methods.

Customizable templates let you tailor forms to each job or site, accommodating different risks. Dedicated apps make planning easier, allowing teams to complete and share plans directly from their phones.

Digital checklists and templates improve workflow by:

- Standardizing PTP across projects

- Creating digital records for compliance

- Making plans instantly accessible onsite

- Streamlining updates and communication

Conclusion

Effective pre-task planning is essential for successful construction projects. A structured approach improves safety, productivity, and outcomes by setting clear objectives, identifying hazards, and assigning responsibilities. Investing time in planning reduces risks and fosters teamwork. Prioritize pre-task planning to ensure project success.