Key Takeaways

- On-site crushing and recycling can drastically reduce costs and environmental impacts by minimizing transportation needs.

- Using recycled concrete and asphalt as material feeds promotes sustainability while supporting solid project economics.

- Adhering to local regulations and industry best practices is essential for safe, lawful, and effective waste management in the construction industry.

Proper disposal and management of construction debris, such as concrete and asphalt, has become increasingly vital as the industry shifts toward sustainability and cost efficiency. Contractors responsible for large or small projects must weigh smart options for reducing waste and meeting local regulations. Modern solutions not only help minimize a site’s environmental footprint but also deliver financial advantages that directly benefit contractors and project managers. For those seeking reliable concrete disposal, understanding innovative practices and industry standards is key to successful project outcomes.

Construction waste, particularly heavy aggregates such as concrete and asphalt, presents challenges in transportation, recycling, and reuse. Implementing on-site recycling technologies and sustainable reuse promotes efficiency and compliance. Responsible disposal is crucial for business growth and community safety, leading to better project outcomes, compliance rates, reduced landfill burden, and increased stakeholder satisfaction in the construction industry.

On-Site Crushing and Recycling

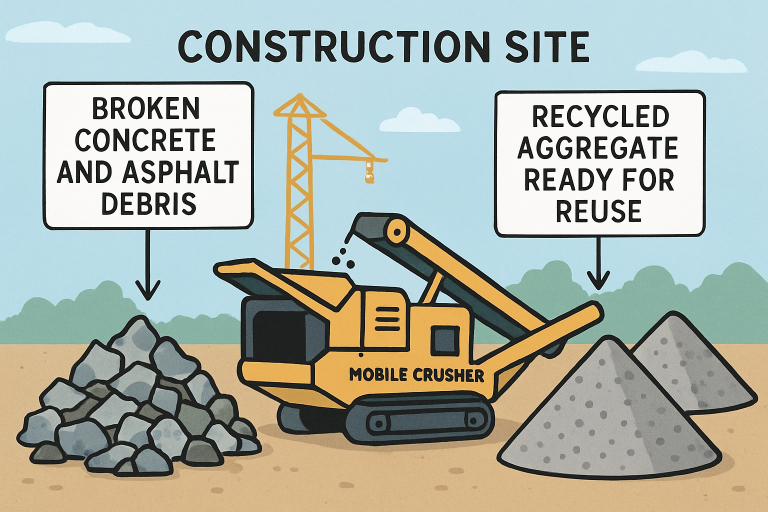

One of the most effective strategies for managing concrete and asphalt waste is on-site crushing and recycling. Mobile crushers and screeners convert demolition debris into reusable aggregates directly on-site, offering several advantages for contractors:

Cost Reduction: Eliminating the need to transport materials to off-site disposal facilities significantly reduces expenses for fuel, labor, and equipment.

Lower Environmental Impact: Recycling on-site minimizes greenhouse gas emissions from hauling, conserves landfill space, and supports broader resource recovery efforts.

Project Convenience: Contractors gain immediate access to remanufactured aggregate, which can be used as fill or base material for other parts of the project, enhancing both efficiency and sustainability.

By integrating advanced mobile processing, construction teams can streamline waste management, reduce costs, and promote environmentally responsible practices, creating a smoother and more sustainable project workflow.

Utilizing Recycled Materials in Construction Projects

The integration of recycled concrete and asphalt into new construction marks a positive shift toward circular economy principles. Modern industry standards support the use of these recycled materials in pavement sub-bases, backfill, and even the mixing of fresh concrete. These practices further reinforce both sustainability and project profitability:

- Resource Conservation: Sourcing usable materials from demolition debris reduces the need for virgin aggregate mining, thereby protecting natural resources and habitats.

- Cost Advantage: Higher availability of recycled materials in the market frequently results in lower raw material costs for builders.

- Reliable Performance: Rigorous processing and testing ensure that recycled aggregates meet performance standards equivalent to those of conventional resources.

Aggregate Industries, for example, has advanced in developing asphalt mixes sourced entirely from recycled inputs, illustrating the industry’s potential for high-quality, fully reclaimed products and substantial cost control. Such innovation not only benefits business but also drives industry-wide sustainability improvements.

Regulatory Compliance and Best Practices

Compliance with local and federal regulations is non-negotiable in the management of construction waste. Regulatory bodies outline necessary steps for permitting, site safety, and quality verification. Adhering to these standards reduces project liability and supports safer work environments:

- Permitting: Acquire and display required local permits to conduct on-site crushing, recycling, and temporary storage of construction waste.

- Workplace Safety: Implement robust training protocols, enforce the use of protective equipment, and regularly monitor environmental controls to safeguard workers and surrounding neighborhoods.

- Material Quality Checks: Implement periodic laboratory testing of recycled products to verify compliance with structural, environmental, and safety benchmarks.

Staying up-to-date with legal obligations and technical advancements is made easier with industry publications and municipal resources that provide evolving guidance.

Implementing a Sustainable Waste Management Plan

A well-structured waste management plan underpins every efficient disposal strategy. Effective plans address unique site needs, anticipated waste volumes, and available technologies. The steps below provide a roadmap for construction teams:

- Initial Assessment: Quantify waste output and identify sources within the workflow, ensuring both major and minor streams are considered.

- Material Segregation: Separate waste types as close to the source as possible, facilitating clean recycling and limiting landfill contamination.

- Strategic Partnerships: Consult with local recycling facilities, mobile crushing service providers, or invest in owned equipment to streamline recycling operations.

- Continuous Training: Commit to routine employee education regarding evolving environmental practices, local requirements, and site-specific handling protocols.

Experienced contractors often highlight that teams with ongoing training and clear roles are more compliant and efficient in waste handling, reinforcing both safety and sustainability gains.

Conclusion

Incorporating efficient concrete and asphalt disposal solutions is a critical step for environmentally responsible and economically sound construction. On-site recycling, strategic reuse of recycled materials, and strict adherence to best practices empower project leaders to curtail environmental damage while strengthening project outcomes. As regulatory expectations grow and sustainability concerns intensify, embracing these practices will ensure ongoing industry leadership and environmental compliance, delivering long-term value to both communities and businesses.