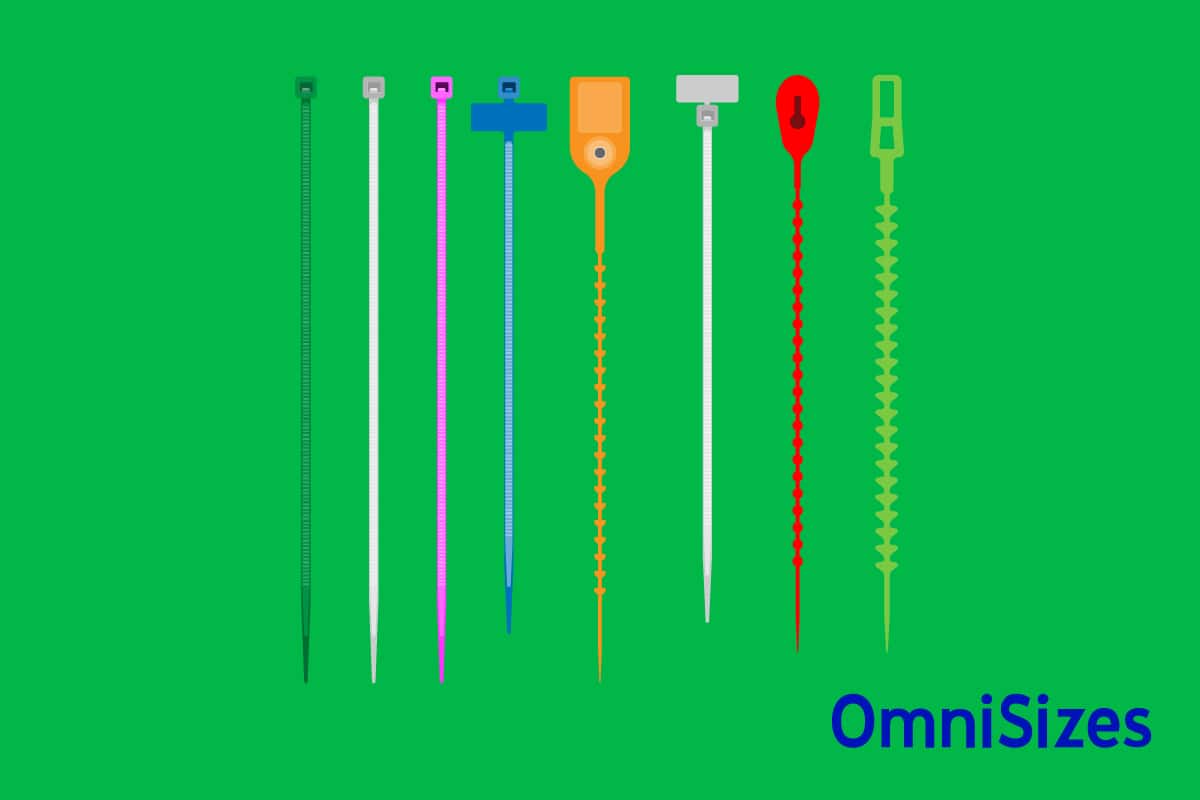

Zip ties have a range of applications that span from simple household fixes to complex industrial solutions. The key to their versatility lies in understanding zip tie size, which varies to accommodate different needs.

The most common zip tie length is 12 inches (30.48 cm). Zip ties are available in lengths ranging from 4 to 48 inches and widths from 2.5 to 9 millimeters. They are used for organizing cables, securing items, gardening, and even in automotive and industrial applications.

This guide will explain common zip tie sizes and their uses, how zip tie strength is measured, and how to choose the right zip tie for any task at hand.

Common Zip Tie Sizes and Their Uses

Zip ties come in a plethora of sizes. Their size usually dictates how they should be used.

Small Zip Ties

Small zip ties typically measure between 4 to 8 inches in length and have a width of around 2.5 millimeters. They are widely used for organizing small cables like those found in home entertainment systems or computer setups. Their small size makes them ideal for managing wires in tight spaces, ensuring neatness and reducing clutter.

In addition to cable management, these ties are handy in crafting, securing small bags, attaching labels to items, or even in gardening for tying small plants and shrubs.

Medium Zip Ties

Medium zip ties are generally found in lengths ranging from 8 to 12 inches with a width of approximately 3.6 millimeters. This size is versatile and can handle a bit more weight and bulk compared to their smaller counterparts.

These zip ties are commonly used in both residential and commercial settings for bundling medium-sized cables, such as those used in offices or workshops. Beyond cable management, they serve well in securing items during transportation, organizing tools and equipment, and even in DIY projects.

Large Zip Ties

Large zip ties are the heavy lifters in the zip tie family, typically measuring from 14 to 40 inches in length with widths ranging from 4.8 to 9 millimeters. These ties are designed for heavy-duty applications and can secure large bundles of cables or pipes in industrial environments.

They are highly valued in construction for securing temporary fencing, holding together heavy-duty materials, and even in automotive applications for bundling larger cables or securing parts.

Extra-Large Zip Ties

Extra-large zip ties are the giants, often exceeding 40 inches in length with a width that can go up to 12 millimeters or more. These are specialized ties designed for the most demanding tasks. They are often used in industrial applications where extreme strength and length are required, such as in securing heavy machinery or large bundles of industrial cables.

Zip Tie Strength

Tensile strength refers to the maximum load a zip tie can handle before breaking. This strength is usually measured in pounds (lbs) and varies across different sizes and materials of zip ties.

Light-Duty Zip Ties

Light-duty zip ties typically have a tensile strength up to 18 lbs. These ties are ideal for simple, low-stress applications like organizing small cords, securing light items, or for use in crafting. They are often used in offices or homes for managing computer cables, attaching tags to luggage, or bundling small household items.

Medium-Duty Zip Ties

Medium-duty zip ties usually offer a tensile strength ranging from 18 to 50 lbs. They strike a balance between strength and flexibility, making them suitable for a broader range of applications.

Heavy-Duty Zip Ties

Heavy-duty zip ties are designed for the most demanding tasks, with a tensile strength exceeding 50 lbs. These ties are robust, often wider and thicker, making them suitable for industrial applications, construction, and heavy automotive uses.

Stainless Steel Zip Ties

Stainless steel zip ties are known for their exceptional strength and durability. They can handle high tensile loads and are resistant to corrosion, heat, and harsh environmental conditions.

UV Resistant Zip Ties

UV resistant zip ties are manufactured to withstand prolonged exposure to sunlight without deteriorating. They maintain their tensile strength and flexibility even after long periods in the sun, making them ideal for outdoor use.

Tips for Choosing the Right Zip Tie Size

While zip ties are incredibly versatile, you need to choose the right zip tie for the task. Follow these tips to ensure you have the right zip tie size in your toolbox.

1. Assess the Application

Different tasks require different strengths and sizes. For lightweight tasks like bundling small cables or attaching tags, small zip ties are sufficient. For heavier applications, such as securing larger cables, pipes, or outdoor uses, larger and stronger ties are needed.

2. Determine the Bundle Diameter

Measure the circumference of the bundle and ensure the zip tie you choose is long enough to wrap around it comfortably. It’s better to choose a zip tie that’s slightly longer than needed.

3. Consider Tensile Strength

Light-duty ties with lower tensile strength are good for simple tasks. For heavier bundles or more demanding environments, choose medium-duty or heavy-duty ties with higher tensile strength. This ensures that the tie won’t break under pressure.

4. Choose the Right Zip Tie Material

Zip ties are typically made from nylon or stainless steel. Nylon is flexible, cost-effective, and suitable for general use. Stainless steel zip ties offer greater strength and durability, especially in harsh environments.