Key Takeaways for Fabrication Shops

- Small workflow improvements can unlock major productivity gains.

- Modern fabrication shop management software helps track jobs, reduce delays, and increase visibility.

- Consistent communication and hands-on employee training set shops up for sustained success.

- Data-driven insights produce faster, informed decisions that boost overall efficiency.

Common Shop Floor Challenges in Fabrication

Every fabrication shop faces common challenges like tight deadlines, material delays, and equipment failures. McKinsey & Company found that poor communication and information flow cause delays, errors, and rework. Inaccurate job info delays production, and unexpected downtime results in lost revenue.

Embracing digital solutions like fabrication shop management software allows fabricators to address many of these pain points. Centralized software tools help teams monitor progress, anticipate material requirements, and resolve issues before they escalate, minimizing unnecessary downtime and optimizing resource allocation.

Workflow Improvements That Drive Results

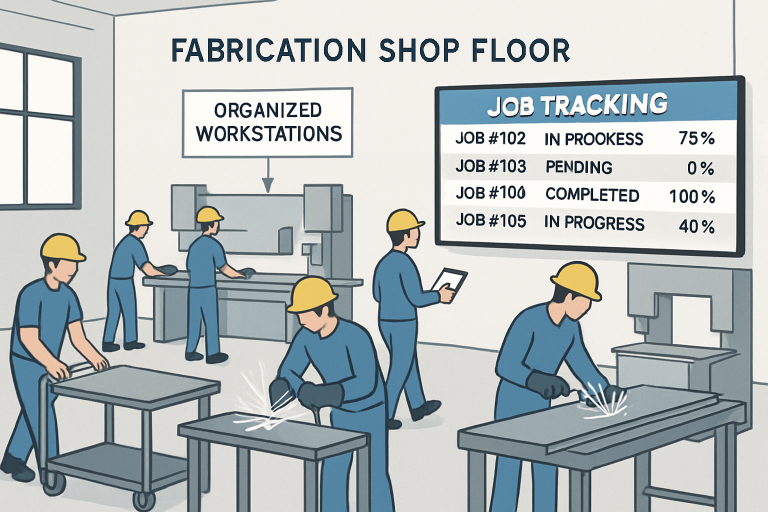

Shop floor efficiency depends on small, deliberate changes like organizing materials, minimizing wasted movement, and using visual cues to cut waste. Case studies show standardized instructions and team huddles can reduce waste by 20% and shorten lead times. Keeping the floor organized with labeled storage saves time and errors. Job tracking helps managers quickly see project status, enabling resource reallocation to prevent bottlenecks. Leading firms review processes regularly to consolidate or automate steps, boosting throughput without extra labor.

Current Technology Trends in Fabrication Management

Digital transformation is reshaping manufacturing with cloud platforms and real-time tracking that boost visibility and issue identification. These tools provide instant insights into project status, inventory, and costs, meeting client expectations. As Manufacturing.net notes, small and midsize shops automate admin tasks like barcode scanning and scheduling, leading to more accurate reporting and quicker decision-making.

Making Data-Driven Decisions for Efficiency

Fabrication shops that effectively analyze key performance indicators like equipment uptime, on-time delivery, scrap rates, and employee productivity can achieve lead time reductions of up to 50%, according to research from the Society of Manufacturing Engineers. This data-driven approach enables teams to establish realistic production targets, objectively track progress, and implement necessary course corrections or preventive maintenance, ultimately transforming shop floor operations.

Training Employees for a Smarter Shop Floor

Building Flexible, Knowledgeable Teams

- Continuous cross-training to cultivate adaptability and team coverage.

- Engaging “lunch and learn” mini-sessions to refresh and build on essential skills.

- Practical, hands-on training for new equipment and digital tools to ensure rapid adoption.

Investing in ongoing learning is vital for cultivating employee buy-in and reducing operational errors. Shops that integrate formal instruction with shadowing programs bring their teams up to speed quickly, especially when rolling out new software tools or production techniques. According to Harvard Business Review, well-trained employees are more engaged, motivated, and less likely to leave further stabilizing shop floor operations.

Collaboration Solutions for Modern Fabricators

Effective communication is the foundation of an agile, mistake-resistant fabrication shop. Tools such as digital message boards, shop floor tablets, and weekly review meetings ensure everyone stays informed, minimizing misunderstandings. Pairing experienced employees with newcomers via mentorships enables rapid skills transfer and flattens the learning curve for new procedures or technologies. Incorporating regular feedback loops, such as end-of-shift check-ins, not only improves morale but also surfaces improvement ideas from frontline workers who know the process best.

Key Takeaways for Fabrication Shops

- Begin with well-organized workspaces and job tracking for immediate efficiency gains.

- Leverage user-friendly fabrication shop management software to remove bottlenecks and boost job visibility.

- Foster communication and continuous improvement with regular team meetings and skill-building programs.

- Let data guide every change track KPIs, monitor processes, and invest in your team for sustainable results.

For fabrication shops of all sizes, embracing these practical steps supports a more predictable, responsive, and profitable operation. By leveraging digital tools and nurturing your workforce, shop floor challenges become opportunities for continuous growth and success.