Key Takeaways

- Roper gear pumps offer reliable, pulse-free transfer of viscous or abrasive fluids across diverse industries.

- Material choices and modern advancements make them suitable for challenging applications and sustainability initiatives.

- Proper installation, maintenance, and technology selection are crucial for optimizing efficiency and operational longevity.

Overview of Roper Gear Pumps and Their Functionality

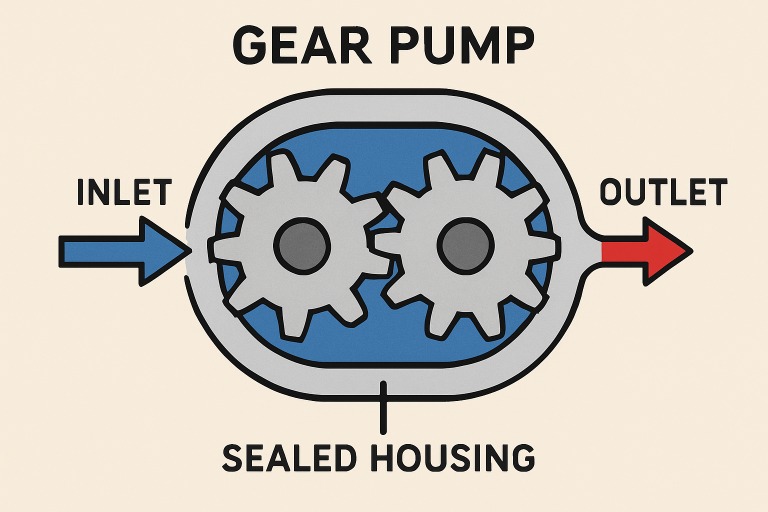

Roper gear pumps are trusted workhorses in various industrial processes, prized for their ability to deliver fluids consistently and efficiently. Built with rotating gears enclosed in a tightly sealed housing, these positive displacement pumps maintain steady flow rates regardless of pressure fluctuations.

As industries seek dependable, long-term solutions for shifting a wide array of fluids, many turn to expert suppliers such as a Summit Pump Distributor. These specialists provide valuable insights into pump specification, installation, and maintenance, ensuring each system is tailored for the operational and environmental challenges.

Key Advantages of Gear Pumps in Industry

- Superior efficiency for handling medium to high-viscosity fluids like oils, syrups, and resins.

- Durability against abrasive or corrosive media when constructed with appropriate materials.

- Pulsation-free operation offering gentle, low-noise delivery—vital in quality-sensitive processes.

- Compact design that fits easily into existing plant layouts with limited available space.

Gear pumps have a simple yet rugged design, making them easy to maintain and reliable in harsh process conditions. This minimal downtime directly translates to better operational productivity, a crucial factor for manufacturers and process plant operators, where stopping or slowing down production is costly.

Choosing the right type of pump for a specific application means balancing these advantages with other considerations, such as flow rates, temperature, and chemical compatibility.

Common Industrial Uses for Gear Pumps

The adaptability of Roper gear pumps is evident in their widespread presence across key industries:

- Food and Beverage: Moving syrups, oils, molasses, and other high-viscosity ingredients using sanitary configurations for contamination-free processing.

- Oil and Gas: Reliable transfer of fuel oils, lubricants, asphalt, or heavy crude with the longevity needed for remote or extreme field conditions.

- Chemicals: Handling solvents, adhesives, and resins where chemical resistance is required, further supported by suitable construction materials.

- Marine: Efficiently moving bilge water, fueling vessels, or facilitating cargo transfer—processes that demand both endurance and reliability at sea.

According to Pumps & Systems, gear pumps’ robust versatility ensures a seamless fit for most closed-loop and transfer applications, especially where viscosity and cleanliness are paramount.

Material Considerations for Challenging Applications

The longevity and performance of any gear pump depend greatly on material choices. Stainless steel or engineered polymers are preferred in highly corrosive or abrasive environments, helping extend service intervals and defend against wear. When handling caustic chemicals or hot fluids, ensuring the pump’s elastomers and gaskets suit the application is critical.

Recent Innovations in Gear Pump Design

Modern gear pumps benefit from innovative upgrades in seals, bearings, and digital technologies. Improved sealing methods and micro-tolerances in gear manufacturing reduce leakage risks and elevate energy efficiency. Furthermore, the integration of real-time digital monitoring allows maintenance teams to assess pump health and schedule interventions before failures occur, quickly becoming an industry best practice.

As highlighted by Pumps & Systems: How to Increase Pump Energy Efficiency, even incremental improvements in pump efficiency and operations deliver substantial energy savings and sustainability benefits over time.

Comparing Gear Pumps with Other Pump Types

Gear Pumps vs. Centrifugal Pumps

Gear pumps maintain reliable flow regardless of system pressure or fluid viscosity—a stark difference from centrifugal pumps, which can struggle to efficiently handle thicker fluids or unstable system loads. Gear pumps offer clear operational predictability for manufacturers with high and variable viscosities.

Gear Pumps vs. Diaphragm Pumps

Diaphragm pumps excel at handling solids in suspension and slurries but may falter under high-pressure demands or when footprint is a concern. With their compact design and ability to generate higher pressures, gear pumps have become preferred for transfer tasks requiring precision and minimal interruptions.

Best Practices for Installation and Maintenance

Reliable performance begins with installing the gear pump on a stable, level base and ensuring precise shaft alignment to prevent premature wear. Including strainers and filters at fluid intakes protects gears and bearings from particulate matter. Regular inspection, lubrication schedules, and advances in predictive maintenance, such as vibration or oil analysis, further maximize lifespan and efficiency.

Future Trends: Toward Sustainability and Efficiency

Industrial sustainability efforts are driving the adoption of smarter, greener pumping solutions. Technologies such as variable speed drives, energy-efficient motors, and eco-friendly lubricants are reducing both power consumption and environmental footprints. Digital monitoring and automation continue optimizing maintenance practices and extending essential equipment’s service life.

Manufacturers who embrace these advancements lower operational costs and remain compliant with tightening industry regulations and expectations for reduced emissions.

Final Thoughts

Roper gear pumps set the standard for reliable, efficient fluid handling in various industrial settings. Their unmatched adaptability, improved by material advances and digital innovations, assures their ongoing relevance as industries strive for greater productivity and sustainability. By collaborating with knowledgeable partners and staying ahead of maintenance and technological trends, companies can secure safe, streamlined operations for years.