Bottle cap dimensions are an often overlooked but essential aspect of product packaging. They serve not only as a seal to protect the contents within but also play a role in branding and ease of use for consumers.

The typical bottle cap found on bottled water measures 30 mm in diameter and 28 mm high (1.2 × 1.1 inches). You can find bottle caps of nearly every diameter, height, and thread pattern.

This guide will further explore the nuances of bottle cap sizes, how to size a bottle cap, and common uses for certain cap sizes.

Fundamentals of Bottle Cap Dimensions

Bottle cap dimensions dictate how well a cap fits, the type of seal it provides, and even how consumers interact with the product.

Materials Used in Bottle Cap Manufacturing

- Plastic Caps: Derived from polymers, plastic caps are lightweight, versatile, and cost-effective. They’re commonly found on water bottles, juices, and many household products. Different types of plastics, like polyethylene (PE) and polypropylene (PP), offer various benefits. PE caps are flexible, while PP caps provide a firmer grip.

- Metal Caps: Metal caps, often made of aluminum or steel, are robust and provide an air-tight seal, making them preferred for carbonated drinks. They’re also recyclable, promoting sustainability. The familiar “pop” sound when opening a soda bottle? That’s a testament to the metal cap’s tight seal.

Standard Sizing vs. Custom Sizing

Standard bottle cap dimensions cater to the most common bottle sizes. This uniformity makes it easier for manufacturers, reduces costs, and ensures compatibility across multiple brands. For instance, most soda bottles have a standard cap size, allowing for consistent production.

Customized cap sizes cater to unique product needs. Maybe a brand wants a distinct look for its product or needs a particular size for functionality. Custom caps might be found on artisanal products, luxury perfumes, or specific pharmaceuticals.

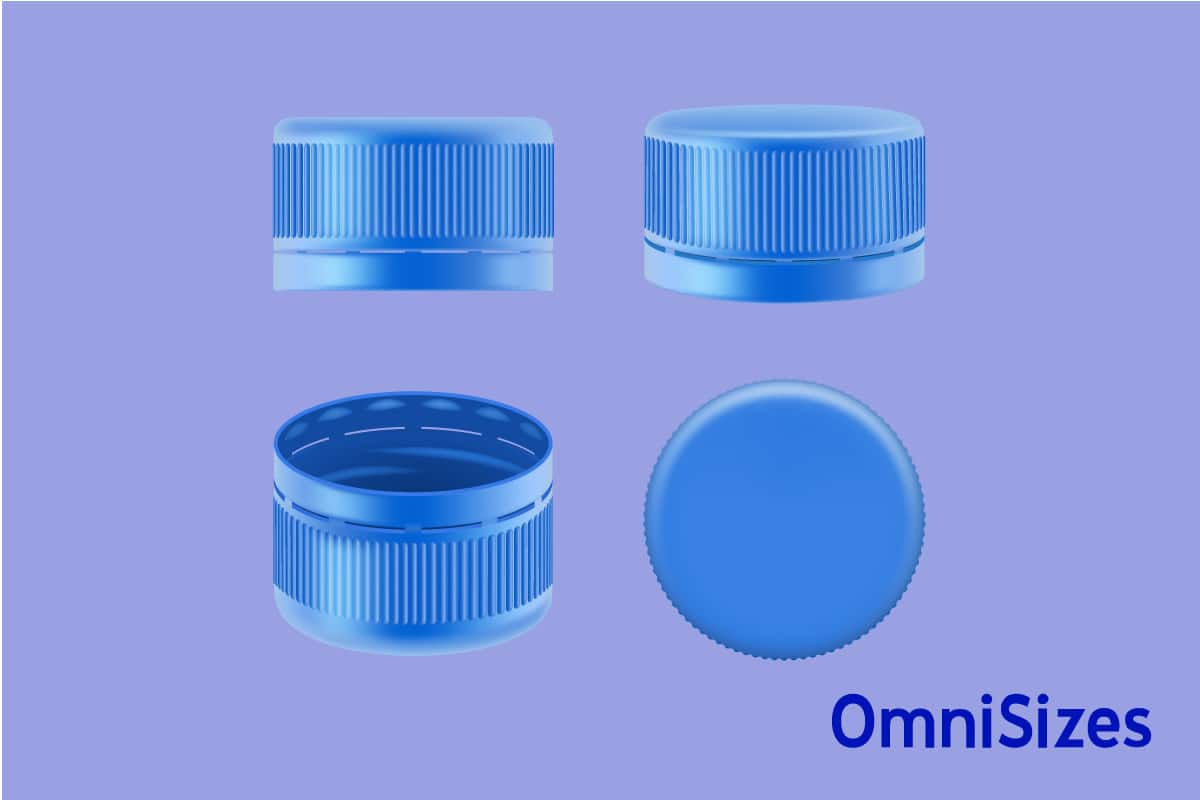

Key Parameters in Bottle Cap Dimensions

The size of the cap typically depends on the container it’s designed to close. For instance, mason jars have wider openings than soda bottles and require wider caps. However, you can usually measure bottle caps based on the following key parameters.

1. Diameter

The diameter of a bottle cap determines how wide it is. This measurement is typically the first consideration when pairing a cap with a bottle. Diameters can vary, but common ones include 30 × 28 mm inches (1.2 × 1.1 inches) for 500ml bottled water and 40 × 60 mm (1.6 × 2.4 inches) for larger ones.

2. Height

Cap height affects how tall or short the cap appears. Taller caps can provide a better grip, while shorter ones offer a sleek look. The height also plays a role in how much torque is needed to open the bottle, affecting user experience.

3. Thread Patterns

The spiral designs you see inside a cap are threads. They help in screwing the cap onto the bottle. Deeper threads provide a stronger grip, while shallower ones allow for quicker opening and closing. The thread depth and design vary based on the bottle’s neck design.

Typical thread patterns per GPI standards include:

- 410 (single and 1.5 thread turns)

- 415 and 425 (2 thread turns for tall and narrow caps, respectively)

- 2000 (non-continuous threads)

4. Liners and Seals

Inside many caps, there’s a liner. As packaging specialist Denika Kisty notes, this component creates a barrier between the cap and the product, offering added protection against leaks or contamination.

There are multiple types of liners, like foam liners for basic sealing, induction liners that bond with the bottle rim, and pressure-sensitive liners that stick to the bottle once the cap is screwed on.

Bottle Cap Dimensions by Use Case

Bottle cap dimensions vary based on their intended use. The type of product, its storage needs, and consumer interaction all influence the cap’s size and design.

Beverage Bottles

- Sodas and Carbonated Drinks: Carbonated beverages require caps that can handle internal pressure. These caps measure around 32 × 5.5 mm (1.3 × 0.2 inches). Their design includes a tight seal to keep the fizz intact.

- Water Bottles: Water bottle caps, especially for single-use bottles, are usually made of plastic. Their size hovers around 30 × 28 mm (1.2 × 1.1 inches). These caps often feature ridges for an easy grip and quick opening.

- Alcoholic Beverages: From beer to wine, the caps for alcoholic beverages differ widely. Beer bottles often use crown caps, which are around 26 mm (1.02 inches) in diameter, while wine bottles employ corks or screw caps that can range from 29 mm (1.14 inches).

Pharmaceutical Bottles

- Prescription Medicine Bottles: Safety is paramount here. Many of these bottles use child-resistant caps, which require pushing down and turning simultaneously. These caps can vary, but the typical cap measures 31.5 mm (1.24 inches) wide.

- Over-the-counter Medicine Containers: While some OTC medicines use child-resistant caps, others might opt for standard screw caps, especially for products like cough syrup. Dimensions here can range from 25 to 28 mm (0.9 to 1.1 inches).

Cosmetic Containers

- Perfume and Cologne Bottles: Caps for fragrances are often about aesthetics as much as function. They can be ornate, with sizes largely dependent on the bottle’s design. Common sizes might be 20 × 30 mm (0.79 × 1.18 inches), but luxury brands might opt for larger, more decorative caps.

- Lotions and Creams: Bottles for lotions or creams frequently use caps with built-in dispensers or pumps. These caps are typically larger, around 40 × 60 mm (1.57 × 2.36 inches), to accommodate the pump mechanism and ensure smooth product dispensation.

Food Packaging

- Sauces and Condiments: For products like ketchup or mustard, caps are designed for easy pouring. Flip-top caps or those with small nozzles are common. Dimensions for these might be in the ballpark of 35 × 5 mm (1.38 × 1.97 inches).

- Spreads and Jams: Jars of spreads or jams often need wider caps to allow for easy access with a knife or spoon. These caps can be quite broad, with heights ranging from 38 to 82 mm (1.5 to 3.2 inches). They offer a tight seal to maintain product freshness.