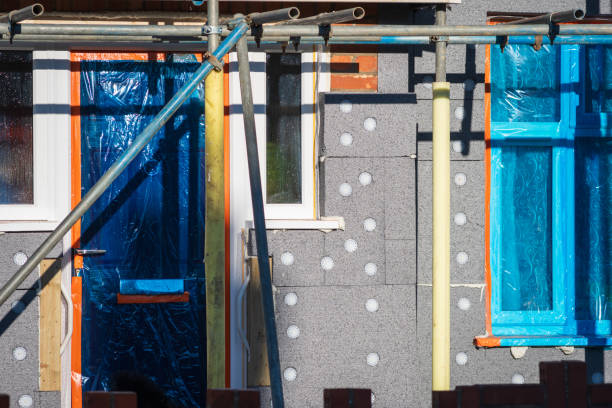

External cladding panels have revolutionized construction efficiency and building performance in ways that make traditional brick-and-mortar seem almost quaint by comparison. Modern panel systems can be manufactured off-site with precision that human hands simply can’t match, then installed in a fraction of the time required for conventional materials. We’re talking about installation speeds of 100-200 square feet per day per worker, compared to maybe 50 square feet for traditional siding methods. Quality control happens in climate-controlled factories rather than on job sites where weather, worker fatigue, and material variations create inconsistencies. Panel systems also integrate insulation, vapor barriers, and weather protection into single components, reducing thermal bridging and air infiltration that plague traditional construction methods. Labor costs typically drop 30-40% compared to stick-built alternatives, while material waste decreases dramatically due to precise factory cutting and minimal on-site trimming.

Speed of Installation That Changes Everything

The construction timeline benefits of panel systems go way beyond just getting the job done faster – though that’s certainly a major advantage when you’re paying construction loans and trying to get tenants or buyers moved in.

Weather delays that can stretch traditional siding projects for weeks become minor inconveniences with panel systems. Most panels can be installed in light rain or moderate wind conditions that would shut down masonry or traditional wood siding work.

Crew efficiency improves dramatically because workers can focus on installation rather than measuring, cutting, and fitting individual pieces. Experienced crews often develop installation rhythms that maximize productivity while maintaining quality standards.

Staging and material handling become much simpler when dealing with larger, pre-fabricated components. Instead of managing thousands of individual pieces, crews work with dozens of panels that can be positioned and secured systematically.

The learning curve for new installers is typically shorter with panel systems because the repetitive nature of the work allows skills to develop quickly. This means contractors can train workers faster and maintain quality even with less experienced crews.

Quality control inspection becomes more straightforward when dealing with fewer, larger components. Building inspectors can evaluate installation quality more efficiently, potentially reducing inspection delays.

Long-Term Performance Benefits

Panel systems typically outperform traditional cladding materials in durability testing, though the specific advantages depend on material choice and installation quality.

Thermal performance stays more consistent over time because panel systems minimize thermal bridging and air infiltration paths. Traditional construction creates hundreds of potential weak points where insulation effectiveness can degrade.

Moisture management improves significantly with properly designed panel systems. Integrated drainage planes and vapor barriers reduce the risk of water intrusion that can cause expensive structural damage over time.

Maintenance requirements often decrease because panel systems have fewer joints and connection points where weather sealing can fail. This translates to lower ongoing costs and fewer headaches for building owners.

Expansion and contraction movements are typically accommodated better in panel systems because engineers can design specific connection details that allow movement without compromising weather protection.

Wind resistance often exceeds that of traditional materials because panels can be engineered and tested as complete systems rather than relying on field assembly of multiple components.

Cost Analysis That Makes Sense

The true cost comparison between panel systems and traditional materials requires looking beyond initial material costs to include labor, timeline, and long-term performance factors.

Labor savings from faster installation often offset higher material costs, especially in markets where skilled construction workers command premium wages. The exact breakeven point depends on local labor rates and material availability.

Reduced construction timeline means lower financing costs, earlier occupancy, and faster return on investment for commercial projects. These soft costs can easily justify higher material expenses.

Waste reduction from precise factory cutting typically saves 10-15% on material costs compared to field-cut materials. This becomes more significant with expensive materials like natural stone or high-end metals.

Equipment requirements may be higher for panel installation, particularly for large or heavy panels that require cranes or specialized lifting equipment. This cost factor varies significantly with building height and site access.

Long-term maintenance cost savings from improved weather resistance and durability can justify higher initial investment, though these benefits accrue over many years rather than providing immediate payback.

Design Flexibility and Aesthetic Options

Modern panel systems offer far more design flexibility than the industrial appearance that characterized early cladding panels, with options that can achieve virtually any aesthetic goal.

Custom panel fabrication allows architects to create unique appearances that would be impossible or prohibitively expensive with traditional materials. Complex shapes, integrated features, and precise color matching become achievable.

Mixed material effects can be created within single panel systems, combining different surface treatments, colors, or textures to create visual interest without the complexity of installing multiple cladding types.

Large format possibilities allow designers to create clean, uninterrupted surfaces that emphasize architectural form rather than surface texture. This approach works particularly well for modern or minimalist design styles.

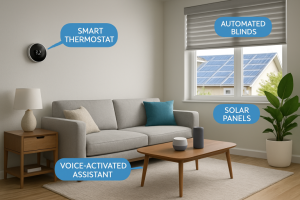

Integration with other building systems becomes easier when panels are designed to accommodate specific mechanical, electrical, or structural requirements. Windows, doors, and penetrations can be precisely located during manufacturing.

Color consistency across large facades improves dramatically with factory-applied finishes compared to field-applied coatings that can vary due to environmental conditions during application.

Environmental and Sustainability Considerations

Panel systems often support sustainable building practices more effectively than traditional materials, though the specific environmental benefits depend on material choices and manufacturing processes.

Reduced construction waste from precision manufacturing and minimal field cutting decreases landfill impact and material costs. This becomes increasingly important as disposal costs rise and environmental regulations tighten.

Energy efficiency improvements from better thermal performance and reduced air infiltration contribute to lower operating costs and reduced carbon footprint over the building’s lifetime.

Recyclability of panel materials varies significantly, but many systems use materials that can be reclaimed and reused at the end of the building’s life. This supports circular economy principles and reduces long-term environmental impact.