Table of Contents

- Why Power Tool Maintenance Matters

- Understanding Basic Power Tool Care

- Battery and Cord Considerations

- Essential Lubrication and Moving Parts

- Updating Components and Accessories

- Storage Solutions to Prevent Damage

- Creating a Maintenance Schedule

- When to Seek Repairs or Replace

- Final Thoughts and Lasting Benefits

Why Power Tool Maintenance Matters

Investing in reliable power tools pays off only if you take the steps to maintain them properly. Skipping regular upkeep can quickly turn a professional-grade tool into an expensive paperweight. Whether you’re a contractor or a hands-on DIY enthusiast, neglecting power tool maintenance leads to avoidable costs both in repairs and unplanned replacements. For those sourcing quality equipment or replacement parts, partnering with major industrial suppliers in North Carolina ensures access to professional advice and genuine components.

Regular care also relies on a broader sense of responsibility. Extending your tools’ lifespan means less electronic waste and a reduced carbon footprint. When fewer tools end up in the landfill, you’re positively contributing to environmental sustainability, aligning with global efforts to reduce hazardous waste from electronics.

Safety is another dividend of thoughtful maintenance. Well-cared-for tools are less likely to malfunction or cause accidents.

Understanding Basic Power Tool Care

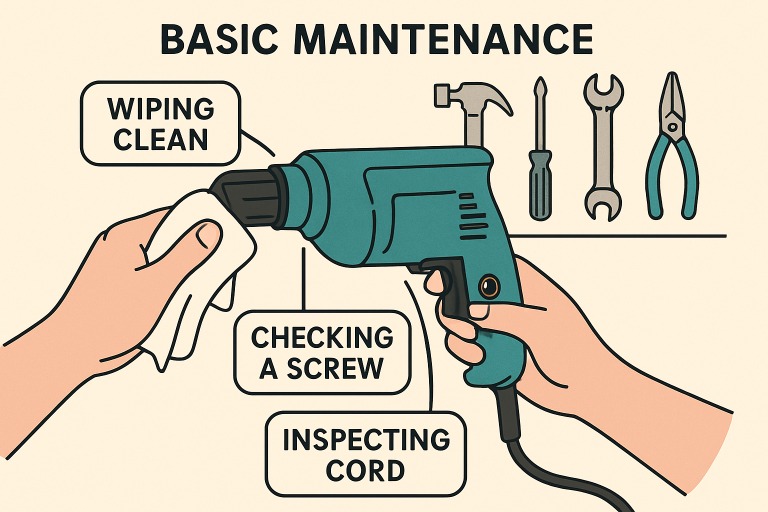

Daily Checks that Make a Difference

Incorporate a daily inspection routine even a quick one before or after each use. Look for loose screws, damaged housings, or signs of excess wear. Confirm that guards are secure and safety features respond as intended. These simple checks can prevent bigger issues down the road.

Quick Cleaning Habits for Longevity

Dust and debris are the silent enemies of power tools. After each project, wipe down surfaces with a clean, dry cloth. Compressed air removes particles from vents, triggers, and intricate parts. Prevent buildup; you’ll preserve internal moving components and motors, ultimately extending tool life.

Battery and Cord Considerations

Storing Rechargeable Batteries Properly

Lithium-ion and nickel-based batteries demand care. Store them in a cool, dry place out of direct sunlight. Never leave batteries fully depleted for long periods charge them to about 50% for extended storage. Excessive heat or cold degrades battery performance and shortens overall lifespan.

Inspecting Cables and Cords

Check cords regularly for cracks, frays, or exposed wiring. Faulty cables are not just a nuisance but a real safety hazard. Damaged cords can lead to shocks or short circuits and should be replaced immediately.

Best Practices for Charging and Using Batteries

Always use your tools’ recommended charger, avoid overcharging, and don’t use batteries that appear swollen or overly hot. Adhering to best charging practices makes batteries last longer and keeps you safe on the job.

Essential Lubrication and Moving Parts

When and How to Lubricate

Lubrication keeps gears, bearings, and moving parts operating smoothly. Refer to your power tool’s manual for specific intervals and the proper type of lubricant. Generally, a few drops on the right spots after cleaning make a noticeable difference, especially for tools like drills, saws, and sanders.

Signs Your Equipment Needs Attention

Squeaking, increased resistance, or visible grime around moving parts are sure signs your tool needs attention. Don’t wait for a breakdown: preventive lubrication costs less than new components.

The Role of Manufacturer’s Instructions

Always consult the manufacturer’s guidelines before applying any lubricant. The right product for one tool could damage another, so use the specific recommendations—including type and frequency provided in your manual.

Updating Components and Accessories

When to Replace Blades, Bits, Filters, and Brushes

Dull or worn-out accessories make tools work harder, reducing performance and lifespan. Replace saw blades, drill bits, air filters, and carbon brushes promptly when they show signs of excessive wear or reduced efficiency. Regular updates ensure optimal performance for every project.

Tips for Keeping Replacement Parts Organized

Store replacements in a designated, clearly labeled box or cabinet. Small bins and labeling help prevent misplacement, and you’ll waste less time searching before each project. Being organized makes a huge difference, especially in busy workshops and garages.

Storage Solutions to Prevent Damage

Climate Considerations for Tool Storage

Avoid storing power tools in damp, unheated garages or sheds. Sudden temperature changes can cause condensation, leading to rust or corrosion. Climate-controlled spaces keep your tools at an even temperature, preserving electrical components for longer.

Organizational Tips for Longevity

Use wall mounts, racks, or cases that keep tools off the ground and protected from accidental drops. Pegboards and modular storage systems can save space and make every tool easy to locate.

Protection from Moisture and Dust

Store power tools in their original cases or use durable storage containers where possible. Silica gel packs and dehumidifiers offer added protection from moisture, while dust covers further shield tools when not in use.

Creating a Maintenance Schedule

Establishing a Routine for Checkups

Set reminders for weekly, monthly, and seasonal inspections. A simple log or checklist ensures nothing is overlooked, especially in busy shops or shared spaces.

Sample Schedules for DIYers and Professionals

Weekend warriors might check tools before each major project, while professionals often inspect tools at the end of every day. Either way, consistent routines ensure early problem detection and reduce long-term costs.

Data-Driven Tips for Seasonal Maintenance

Take time at least twice a year for example, before and after peak usage seasons to conduct deep cleans, check for hidden damage, and follow comprehensive guides.

When to Seek Repairs or Replace

Warning Signs that Indicate Professional Help

If your tool emits unusual noises, smokes, vibrates excessively, or delivers inconsistent performance, it’s time to consult a professional. Attempting major repairs yourself could void warranties or cause further damage. Always unplug or remove batteries before troubleshooting.

Weighing Repair Costs Versus New Purchases

Assess repair costs versus the price of a new tool and consider factors like frequency of use, brand support, and remaining warranty. Sometimes, replacement makes more sense than a costly or unreliable fix.

Final Thoughts and Lasting Benefits

Regular maintenance transforms power tools from disposable assets into long-term investments. The benefits range from saving money to fostering safer worksites and supporting a greener environment. Apply these maintenance tips today for a more efficient, sustainable, and productive workshop.